Project Summary

This project evaluates embodied carbon calculation methods in the timber industry through a literature review and industry consultations. It will assess current carbon accounting practices and compare them with the ISO 13391 series standards, which provides detailed frameworks for calculating carbon footprints across the wood product value chain. Additionally, the project will examine whether these standards are comparable to those used for other construction materials, such as concrete and steel, to promote consistency and transparency in embodied carbon assessments across the construction sector.

DBI Partner

Key Objectives:

- Evaluate current methods for calculating embodied carbon in the timber supply chain.

- Assess the draft ISO 13391 standards and compare them with existing methodologies.

- Compare timber standards with embodied carbon calculations used for other materials.

Project Focus Areas

- Embodied carbon calculation methodologies for timber.

- Comparison of draft ISO standards with current methods.

- Harmonising carbon accounting practices across various materials.

Expected Outcomes:

This project aims to:

- Comprehensive review of existing carbon accounting methods in the timber industry.

- Evaluation of the draft ISO 13391 standards for timber carbon calculations.

- Comparative analysis of timber’s carbon methodologies with other construction materials.

- Recommendations for harmonising embodied carbon calculation methods across the industry.

Timeline and Budget:

The project will span over six months in 2025 with a total budget of $50,000. Key activities includes literature review, industry consultation, and development of carbon calculation methodologies for timber.

Project updates

2025 Report

Project overview:

Timber plays a pivotal role in Australia’s building industry, valued for its versatility, aesthetics, and structural performance. Beyond functional use, timber holds substantial potential for decarbonising the Australian construction sector due to its ability to sequester atmospheric CO₂ during tree growth and its lower embodied carbon compared to traditional materials like steel and concrete. The use of robust accounting methodlogies quantify these claims. LCAs and EPDs are gaining popularity to demonstrate environmental credentials. This project explored embodied carbon calculation methods for timber. It supports informed decision-making and encourages the adoption of timber-based solutions to decarbonise the built environment.

Project progress highlights:

The adoption of the newly published ISO 13391 (parts 1 2 & 3) standard series and ISO/TR 25080 in 2025 represents a step forward for timber embodied carbon accounting, particularly in defining biogenic carbon sequestration.

Project impact:

This project highlighted potential issues in system boundary inclusions across all supply chains and discrepancies in comparative reporting for entities that have chosen to include only A1-A3 (cradle to gate) and those that include A1-A5 (cradle to grave). These discrepancies arise from assumptions in the end or life fate and timing. The benefit of timber based products reutilised in cadscading lifecycles can best be captured in A1-A5 reporting (cradle to grave).

Future work:

Assumptions in the end or life fate and timing, underpin the overall credibility of both Life Cycle Assessments (LCAs) and Environmental Product Declarations (EPDs) and their asscoiated standards. It is recommended that further detailed research is completed to directly compare each stage of the supply chain, inclusive of A1 to A5 for timber, steel and concrete for comparative building product scenarios to accurately quantify the significance of the end-of-life fate and timing.

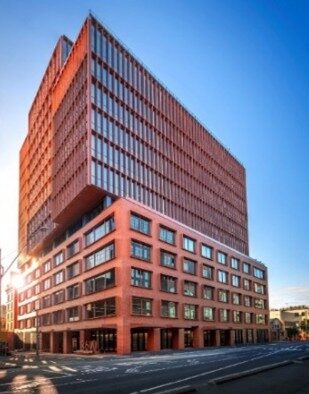

T3 Collingwood (image source: T3 Collingwood, Victoria, Australia), 1688 tonnes carbon stored (XLam, Hyne, Australia).

For inquiries, please contact:

- Adam Faircloth (Team Leader) – adam.faircloth _at_ dpi.qld.gov.au